The world of 3D printing has opened us up to an entirely new era of manufacturing. We can print objects at home using the best budget 3D printers and it's amazing how far we've come yet you'll still be hard pressed to find examples of 3D printing in space. This is mainly due to the volatility of 3D printed materials and a need for extreme reliability in aerospace. But, Horizon Microtechnologies, has recently passed testing standards, put in place to ensure the reliability of materials used in the space industry — bringing us one step closer to introducing more 3D printing components in space.

The 3D printed materials were put through outgassing tests. The materials must meet specific requirements to be cleared for space travel in accordance with ECSS-Q-ST-70-02C, a material screening standard set by the European Cooperation for Space Standardization.

"This Standard describes a thermal vacuum test to determine the outgassing screening properties of materials proposed for use in the fabrication of spacecraft and associated equipment, for vacuum facilities used for flight hardware tests and for certain launcher hardware."

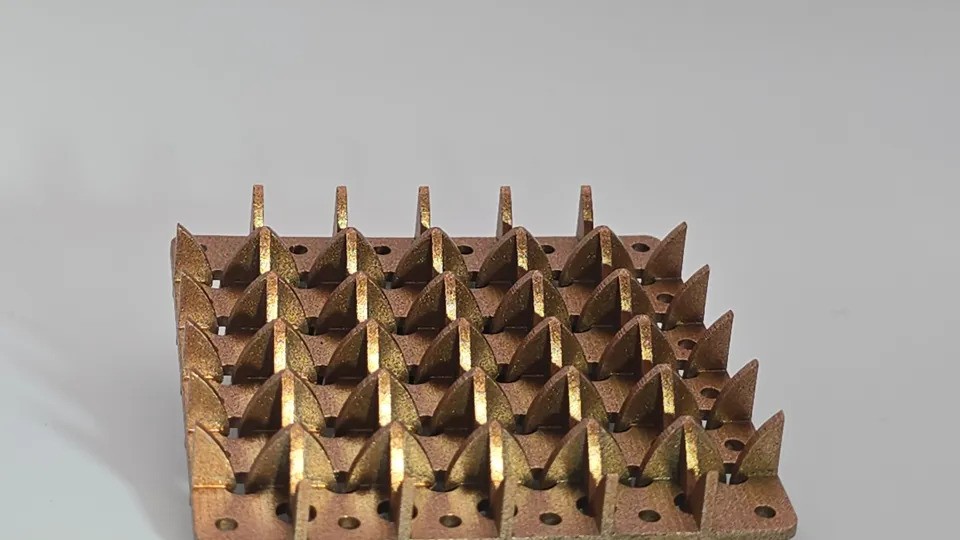

The company accomplished this impressive feat by coating the 3D printed components.

Horizon Microtechnologies CEO Andreas Frölich expressed enthusiasm for the successful results, remarking at the significance of their development. The coating process ensures the 3D printed structures are able to meet the rigorous standards put into place to ensure safety during space travel.

The outgassing testing process in particular is used to determine how much, if any, volatile material is released and/or reabsorbed by the given component being tested. This testing process is also looking out for any cross contamination with nearby items that might be able to absorb any released particles.

By coating their 3D printed components using its own purpose developed coating method, Horizon Microtechnologies was able to successfully pass the standard requirements for the outgassing tests. This means we'll likely see more 3D-printed hardware in wide variety of future space technology, including vessels, satellite hardware and more. Recently, tests were carried out on the International Space Station (ISS) which saw astronauts on the ISS 3D print objects in micro-gravity. This uses low-temperature plastics instead of traditional filament, as all sources of heat and fire are strictly controlled on the ISS. The benefits of 3D printing in space are chiefly the ability to fabricate a part without the expense of a launching a rocket to the station. Just open up a spool of filament, load up your slicer and print that vital part.

If the thought of using 3D printing in the space industry sounds appealing, you're not alone. There's tons of potential to be had between the two but you'd better get a good foothold on 3D printing first. If you're new to 3D printing, check out our list of best 3D printers to see which ones we recommend for everyone from beginners with little experience to pros looking for an upgrade.

Follow Tom's Hardware on Google News to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button.

3 months ago

20

3 months ago

20

English (US) ·

English (US) ·