Where most would buy a dedicated water block for their processor, crafty Chinese YouTuber octppus machined a cold plate directly from their CPU's IHS, via UNIKO's Hardware at X. Testing this approach to yield tangible data required some rather unwieldy strategies, like drawing water from a bucket to ensure a controlled environment. While the idea of carving a water block from your IHS seems ingenious, it carries the obvious risk of destroying your CPU and presents some quirky thermal characteristics.

Why would you even do this in the first place? Your CPU's die is connected to the IHS (Integrated Heat Spreader) by STIM or thermal grease. To liquid cool your CPU, a metal block (or cold plate) is essential to conduct heat from the IHS. Water blocks contain intricate microchannels or streams, where the heat from the block's metal is transferred to the coolant via convection. Since each interface or surface increases thermal resistance, serious overclockers typically remove the IHS and mount the water block directly onto the die.

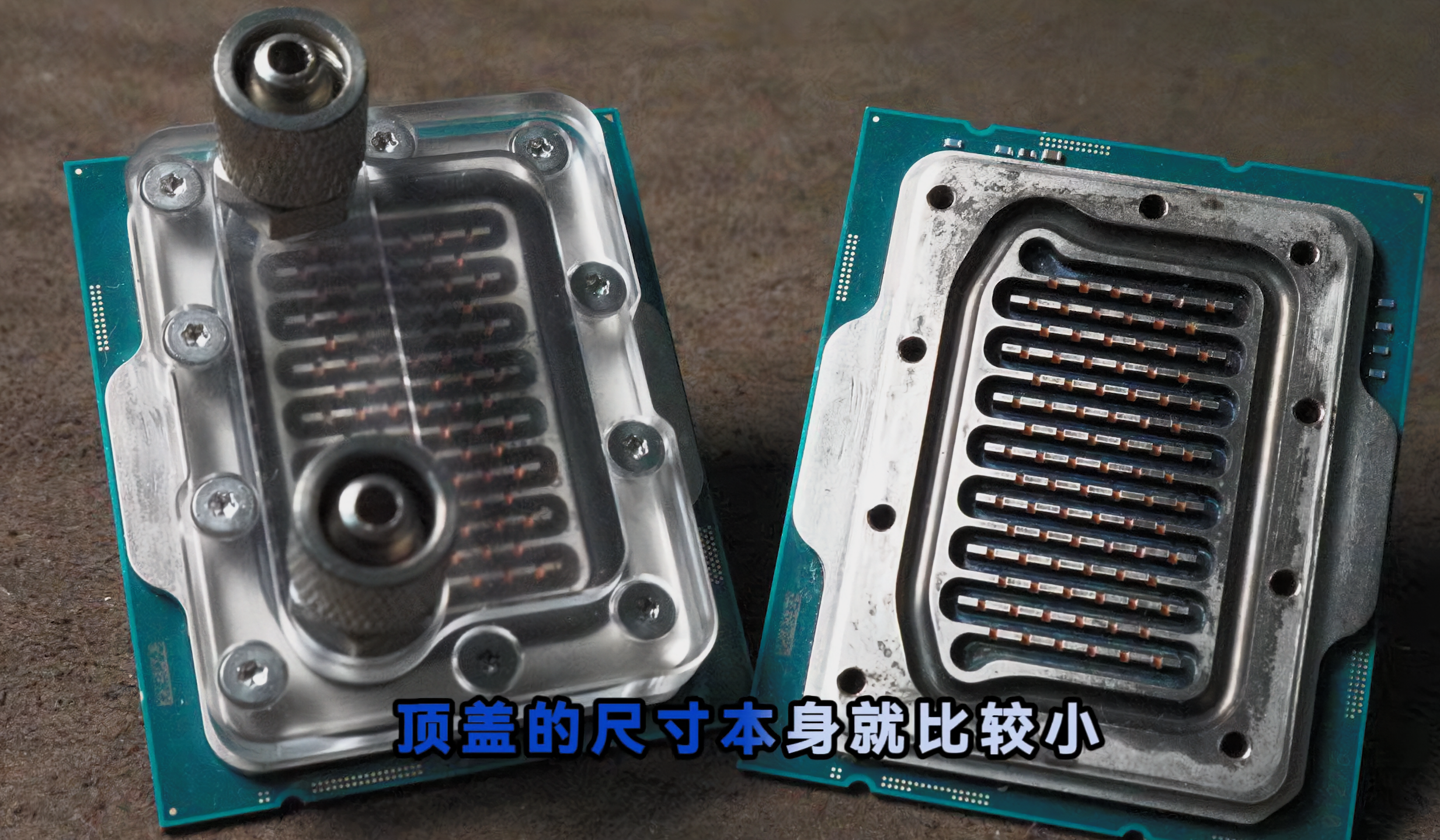

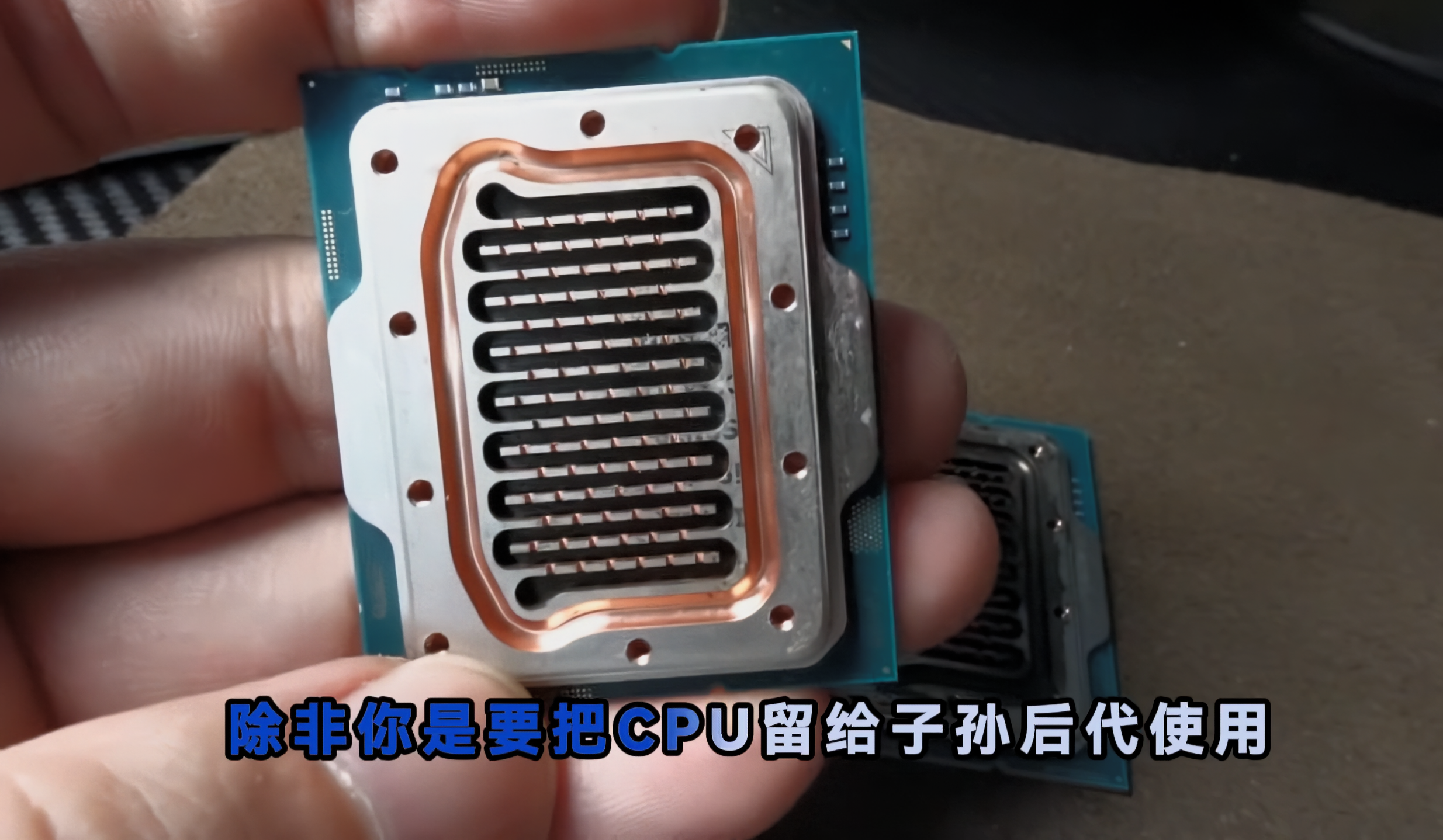

What if you took this the other way around, and removed the external waterblock instead? With the help of CNC machines, in collaboration with a viewer, the modder was able to carve a series of interconnected channels or streams in the IHS of their Core i9-14900KS for the coolant. There are also visible areas for the inlet and outlet fittings, and the entire structure is enclosed in a screwed-in gasket to ensure a leak-proof design.

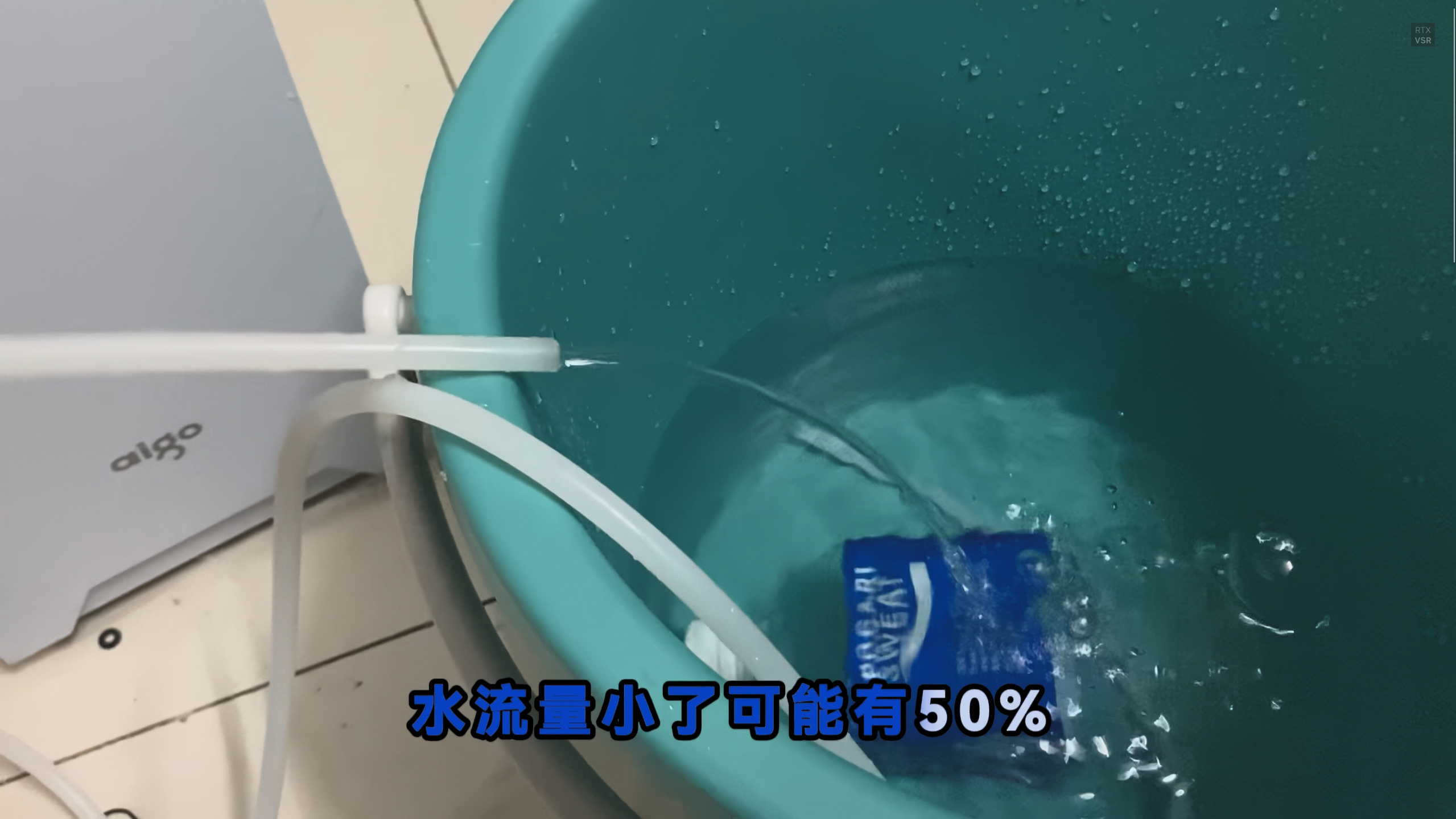

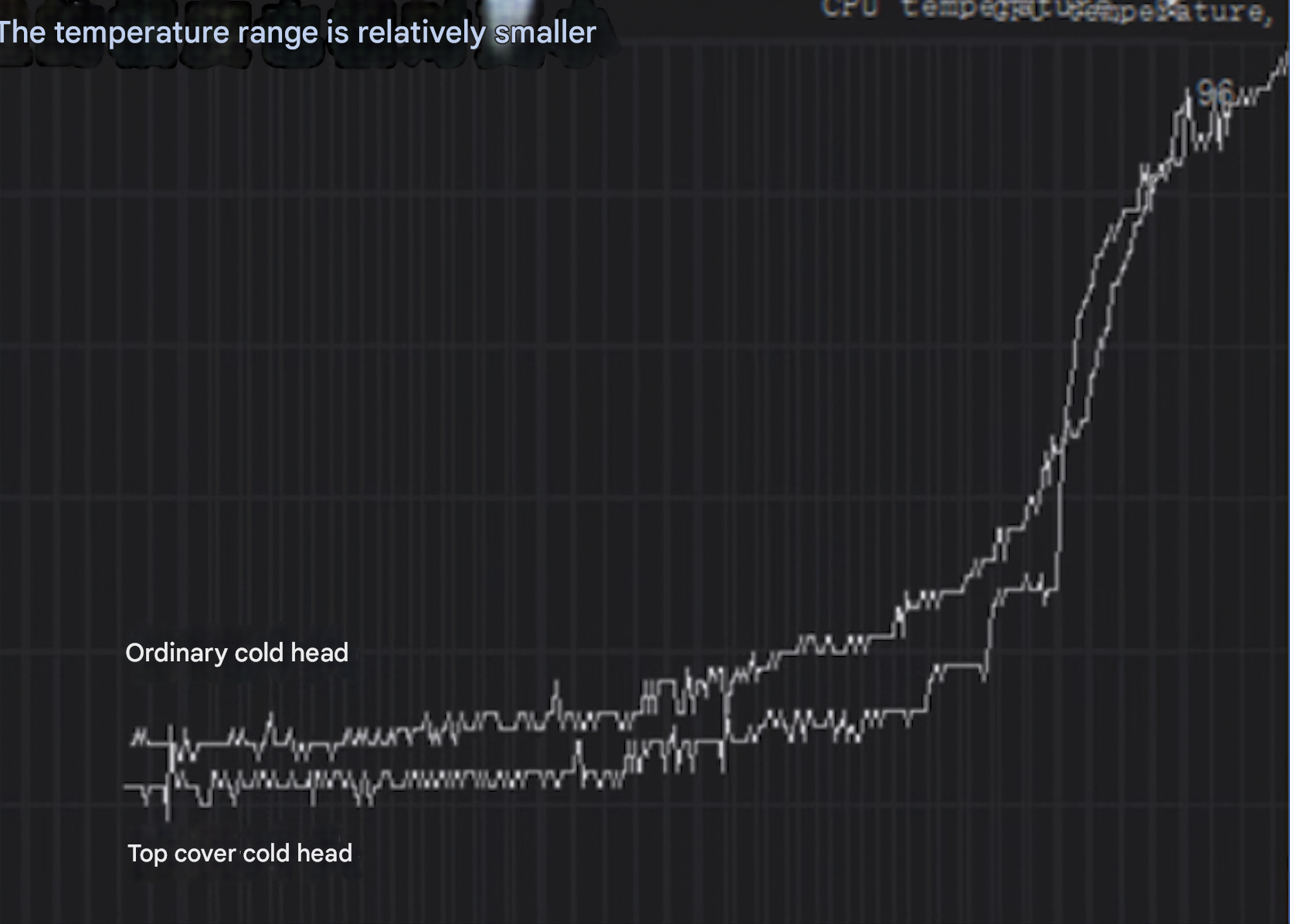

To maintain a constant temperature for the coolant, it was poured into a bucket, which served as the reservoir. After each pass, the coolant was discharged into a separate bottle. That's one way of doing things, I guess. Either way, the pump speed was gradually lowered, and the user plotted the temperature of their modified IHS and a standard liquid cooler on a temperature-time graph. While idling and under a 60W load, the custom IHS cold plate ran cooler. Yet, as the pump speed was reduced, the temperature immediately began to climb, exceeding the conventional liquid cooler.

There's likely a good reason why this happens. The custom IHS solution, per the modder, shortens the distance from the CPU's die to the coolant by a factor of four. And that will have a noticeable impact. However, the tradeoff comes in the form of a smaller surface area and a design that's likely less optimized than traditional water blocks. Unlike cold plates, which spread heat, this approach focuses it in one area, which could explain the rapid temperature increase as shown in the graph.

That being said, for those who live on the edge, machining an IHS into a water block might still prove a viable method, as long as the coolant flow rate is kept in check. This really isn't practical for the average user, and even seasoned veterans might have a tough time getting the execution right. However, it would be great to see a follow-up with a more thorough examination and potentially better designs.

Follow Tom's Hardware on Google News to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button.

7 months ago

18

7 months ago

18

English (US) ·

English (US) ·