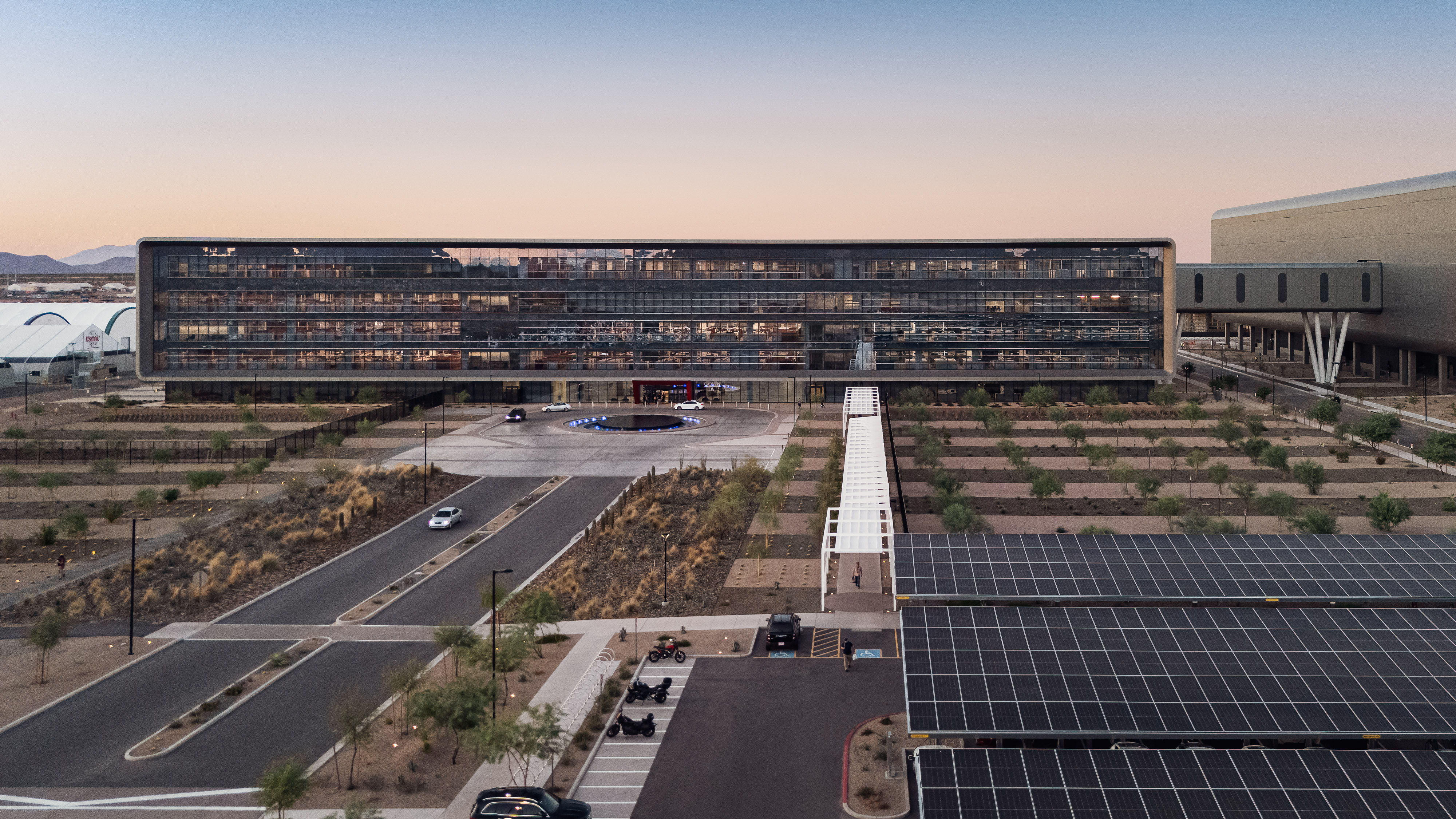

MediaTek is negotiating production of certain chips in the U.S. with TSMC in a bid to meet customer requirements for locally manufactured components. While the plan is still under evaluation, if MediaTek manages to place orders through TSMC's Fab 21 in Arizona, it will be the first non-American company to demand production of its chips at the site. While chips made by TSMC in the U.S. are more expensive than those fabbed in Taiwan, U.S. production may enable MediaTek to address certain customers and/or avoid potential tariffs.

Word of MediaTek's intentions comes from the company's Corporate Vice President JC Hsu, reports Nikkei. The plans target two specific categories: automotive parts and chips tied to more regulated or strategically sensitive applications. The move is said to comply with demands from American clients who favor domestic production for logistical and policy-related reasons. Hsu stressed that the deal has not been formally inked yet.

Unfortunately, the high-ranking executive of MediaTek never revealed when the company plans to produce chips at TSMC's Fab in Arizona or which process technology it intends to use. To that end, it is unclear what exactly MediaTek plans to make. Perhaps the company is ensuring that it can place orders with TSMC U.S. in case it has clients that demand production in America, or there is insufficient capacity in Taiwan. Apparently, there are over a dozen companies interested in making chips on TSMC's N2 fabrication process, so it might be crucial for a big company like MediaTek to secure a portion of TSMC's N2-capable capacity that is set to be located in the USA.

However, whether MediaTek can produce automotive-grade chips at TSMC's Arizona fab (Fab 21) depends on multiple factors — the most critical of which is whether TSMC Fab 21 is compliant with the automotive quality management standard IATF 16949, or at least capable of supporting customers that are. As of now, TSMC Arizona has not publicly disclosed IATF 16949 certification, and the fab was initially focused on consumer and AI/HPC processors using N5 and N4 processes. Without formal IATF 16949 compliance — or documented automotive-qualified production flow — it would be difficult for MediaTek or any other chip designer to use this fab for safety-critical automotive products, especially for applications requiring AEC-Q100 qualified components.

While MediaTek itself does not necessarily need to be IATF 16949 certified, it must ensure that all entities in its supply chain — including process technology, foundry, OSAT, and others — meet the necessary automotive quality and traceability requirements. TSMC offers N5A, N4A, and N3A process technologies that are tailored for automotive applications, so they may include relaxed rules to boost yield and reliability, and production on these nodes usually involves tighter SPC (statistical process control) and defect detection. However, we do not know whether Fab 21 supports such flows.

That said, unless TSMC Arizona eventually adopts or mirrors the automotive-grade flows of the foundry's Taiwan fabs, it is unlikely that MediaTek could produce fully automotive-qualified silicon there for anything other than non-safety-critical infotainment or connectivity chips. For advanced driver-assistance systems (ADAS), powertrain, or battery management chips that require ISO 26262 and ASIL certifications, MediaTek would either need to wait for TSMC Arizona to offer certified flows or continue to rely on TSMC's mature automotive fabs in Taiwan.

Follow Tom's Hardware on Google News, or add us as a preferred source, to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button!

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

3 months ago

48

3 months ago

48

English (US) ·

English (US) ·