Serving tech enthusiasts for over 25 years.

TechSpot means tech analysis and advice you can trust.

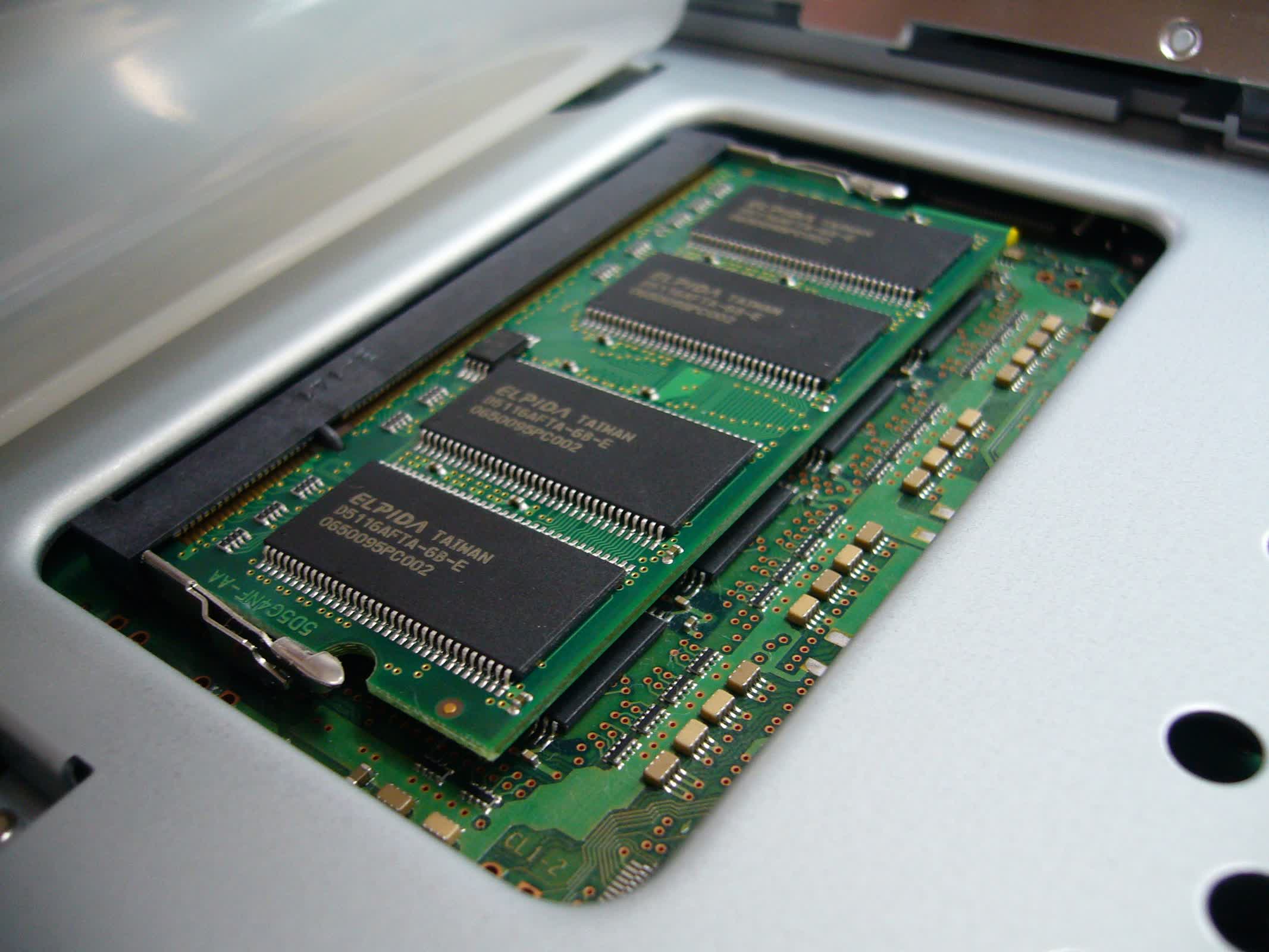

Forward-looking: The once-thriving era of dynamic random access memory production in Germany, driven by companies like Infineon and Qimonda, faded as the economics of commodity memory manufacturing became unsustainable in Europe. Now, a new partnership between Ferroelectric Memory Co. and Neumonda aims to revive the nation's semiconductor ambitions with DRAM+, a non-volatile memory technology powered by ferroelectric hafnium oxide (HfO₂).

FMC specializes in leveraging hafnium oxide (HfO₂) – a material with ferroelectric properties – to develop memory that retains data even when power is lost. This technology replaces the traditional capacitor found in DRAM with a non-volatile alternative, delivering high performance while improving energy efficiency and data persistence. The resulting memory, branded as DRAM+, is poised to transform industries such as artificial intelligence, automotive, medical technology, consumer electronics, and industrial systems.

The shift to HfO₂ represents a major advancement over earlier ferroelectric memory technologies, which relied on lead zirconate titanate. PZT-based ferroelectric RAM (FeRAM) faced scaling limitations at smaller nodes and challenges integrating with standard CMOS processes, restricting its use to memory capacities of only a few megabytes. HfO₂ addresses these limitations, offering a path forward for more scalable, high-density memory solutions.

Unlike PZT, HfO₂ is fully CMOS-compatible, scales below 10 nanometers, and integrates seamlessly with existing semiconductor manufacturing processes. These advantages allow for higher memory densities and performance levels that rival conventional DRAM, potentially reaching gigabit or even gigabyte capacities.

"FMC was founded to exploit the ferroelectric effect of HfO₂ for semiconductor memories," said FMC CEO Thomas Rueckes. "Applied to DRAM, it transforms the capacitor into a low-power, non-volatile storage device while maintaining high DRAM performance. This creates a revolutionary memory ideal for AI compute."

Neumonda brings decades of memory design and testing expertise to the partnership, leveraging advanced platforms like Rhinoe, Octopus, and Raptor. These systems offer low-cost, energy-efficient testing capabilities that streamline development and deliver detailed, independent analyses not possible with conventional equipment. The company claims its platforms can reduce testing costs by 1,000x and energy consumption by 100x compared to traditional methods, while accurately simulating real-world industrial conditions to better predict memory performance.

Neumonda CEO Peter Poechmueller sees FMC's DRAM+ as an ideal proving ground for their technology. As Neumonda's test platforms evolve, FMC's products serve as a showcase for their capabilities while supporting high-yield production, he noted. He also emphasized that the partnership marks a significant step toward reestablishing semiconductor memory manufacturing in Germany.

The collaboration between FMC and Neumonda represents more than just technological progress: it signals a broader revival of European semiconductor capability. By combining FMC's HfO₂-based memory innovation with Neumonda's cutting-edge testing infrastructure, the two companies are laying the groundwork for a localized ecosystem capable of designing and manufacturing advanced memory products.

The stakes are high as Germany seeks to reclaim its place at the forefront of global semiconductor innovation. With non-volatile DRAM+ poised to meet critical needs across AI computing and beyond, FMC and Neumonda are not only advancing memory technology, they are also reigniting Europe's legacy in the field, a move that could reshape the industry for years to come.

English (US) ·

English (US) ·